Specification parameters

Packaging capacity: 150-180 bags/hour

Packaging weight: 25kg/bag

Rated voltage: 380V ± 10% 50HZ

Power: 2KW

Gas consumption: 175Nm ³/hour

Weight: Approximately 1 ton

Applicable bags: paper bags, heavy film bags (thickness 0.18-0.25mm)

Bag size: Width (400-600) mm x Height (700-1100) mm

Equipment size: 3920 × 3160 × 2200MM (standard equipment)

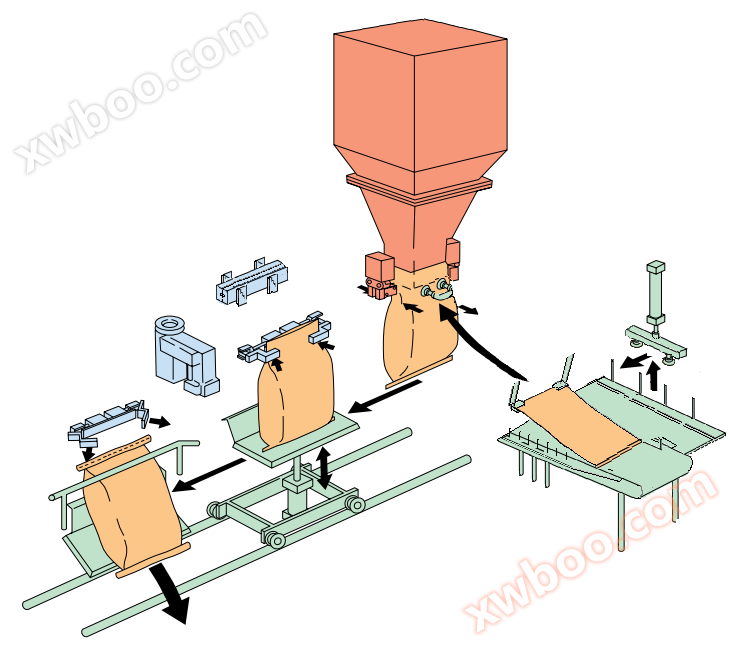

Sketch Map

1. Bag storage

Arrange the bags neatly with the top opening facing forward. The bag storage can hold approximately 50 bags.

2. Bag extraction unit

Take one bag at a time, move it horizontally, and then place it in the empty bag shaping position.

3. Empty bag plastic surgery

Each bag has a ruler on both sides that retracts and tightens to ensure the center position of the bag.

4. Bag clamping and feeding device

After clamping both sides of the bag with 30mm wide clips, it is sent to the feeding port.

5. Bag opening device

Pull the bag mouth with a suction cup and release it using a vacuum generator. When the vacuum opens the bag opening, the clamp moves inward.

5. Discharge port

Specially designed expansion nozzle (traditional funnel rotating 90 degrees) is used to fill the product. The clamp extends after filling to unfold the corner brace.

6. Platform trolley and bag bottom tapping device

At the beginning of loading, the conveyor trolley moves to the unloading position. The bottom tapping plate supports the bag from below, tapping the bag to exhaust and compact the material.

7. Bag sealing machine

After the bag filling is completed, it is directly tightened by the heating device on the carrier trolley and then heat sealed at the bag opening, or sent to the sewing machine for sewing at the bag opening.

8. Bag pouring device (optional for customers)

When the sealed bag is directly transported to the designated position by the loading cart, the bottom plate of the cart tilts to invert the bag and send it to the next stage or directly place the bag on the next conveyor.